- Bộ lập trình PLC, cáp lập trình

- Màn hình HMI

- Cảm biến, phụ kiện

- Biến tần, khởi động mềm

- Máy cắt, Aptomat, khởi động từ

- Thiết bị đo lường, bảo vệ

- Thiết bị công nghiệp, tự động hóa

- Thủy lực, khí nén, van công nghiệp

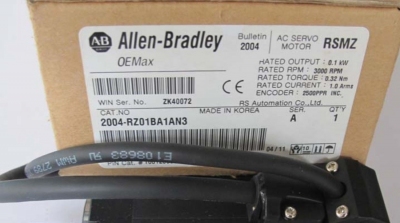

- Motor, Servo motor, Servo Amplifier

- Thyristor, Module, SCR, SSR, Diode

- Phụ kiện tủ điện và vỏ tủ điện

- Cáp điện, ống bảo vệ cáp

- Thiết bị điện trung thế, truyền tải

- Thiết bị chống sét, kim thu sét

- Dụng cụ cầm tay, dụng cụ tool

- ATS, UPS, tụ bù, cuộn kháng

-

Thiết bị ngành xi măng, thép, nhiệt điện

-

Thiết bị thanh lí-hàng tháo máy

CHỔI THAN MORGAN D374N 25X32X60MM

Chổi than Morgan D374N 25x32x60mm

Tình trạng sản phẩm:

- Brand: Shanghai carbon brush

- Model: J164 D172 J204 CH17 J203

- Origin: Mainland China

- Province: Shanghai

- City: Shanghai

- Color classification: J204 25*32*60 J204 20*40*60 J203 25*32*60 J205 25*32*60 J230 25*32*60 MG70 25*32*60 MG70 30*40*60 D172 25*32* 60 D104 25*32*60 CH17 25*32*60 MG50 25*40*60 MG50 32*40*60 MG50 32*40*50 MG50 25*32*60 MG50 25*32*65 MG50 25*32*50 MG50 20*40*60 CH17 25*32*65 CH17 25*32*60 CH17 20*40*60 J164 25*32*60 J164 20*40*60 J201 10*25*60

| Brush Type and Model | |||||||||

| category | series | material | Representative model | ||||||

| graphite brush | S | natural graphite | S3 S6 | ||||||

| Electrochemical graphite brushes | D1 | graphite base | D104 D106 D172NM | ||||||

| D2 | Coke base | D202 D213 D214 D215 D252 D280 | |||||||

| D3 | carbon black base | D308 D308L D309 D312 D374 D374B D374D D374F D374L D374BL D374DL D374N D374S D376 D376N D376Y | |||||||

| D4 | Charcoal based | D464F D479 | |||||||

| Metal graphite brush | J1 | Copper graphite without binder | J100 J101 J102 J103 J104 J105 J113 J151 J164 | ||||||

| J2-1 | Binder high copper graphite | J201 J204 J205 J213 | |||||||

| J2-2 | Binder Low Copper Graphite | J203 J206 J220 | |||||||

| R | Artificial resin binder graphite | R051 R104 R126 R115 R201 R453 R1270 | |||||||

| Remarks: 1> Prefix: S-graphite brush, D-electrochemical graphite brush, J-metal graphite brush. R - synthetic resin binder brushes. 2> Suffix: NM, L, N, S, Y, F - code of stains. 3>R series: the last two digits are the serial number, and the first digits are the hundreds digits of the resistivity. | |||||||||

| Models, features and main application areas of some brushes | |||||||||

| model | Basic Features | Main application range | |||||||

| S-3 | Lower hardness, better lubricity | DC motor with normal commutation, uniform load and voltage of 80V-120V | |||||||

| S-4 | High-resistance graphite brushes with natural graphite as matrix and resin as binder, with low hardness and friction coefficient | Motors with difficult commutation, such as motors with AC commutators, high-speed micro-DC motors | |||||||

| S-6 | Porous, soft graphite brushes with low hardness | Turbogenerator slip ring, 80-230V DC motor | |||||||

| D104 | Low hardness, good lubricity, good commutation performance | Generally used for 0.4-200KV DC motors, DC generators for charging, DC generators for steel rolling, steam turbine generators, winding rotor asynchronous motor collector rings, welding DC generators, etc. | |||||||

| D172 | Good lubricity, low friction coefficient, good commutation performance | Slip rings of large steam turbine generators, exciters, slip rings of hydro generators, DC motors with normal commutation | |||||||

| D202 | High hardness and mechanical strength, good lubricity. Shock and vibration resistance | Traction motors for electric locomotives, DC generators with a voltage of 120-400V | |||||||

| D207 | High hardness and mechanical strength, good lubricity. Good commutation performance | Large steel rolling DC motor, mining DC motor | |||||||

| D213 | Higher hardness and mechanical strength than D214 | Generators for cars and tractors. Traction motor with mechanical vibration | |||||||

| D214 | High hardness and mechanical strength, good lubrication and reversing performance | The exciter of the turbo-generator, the DC motor with the impact load with the voltage above 200V, such as traction motor, steel rolling motor, which is difficult to change direction | |||||||

| D215 | |||||||||

| D252 | Medium hardness, good commutation performance | Difficult commutation, DC motors with voltages of 120-440V, traction motors, exciters for turbo-generators | |||||||

| D308 | Hard texture, good resistivity, good commutation performance | DC traction motors with difficult commutation and small DC motors with high angular velocity. and motor amplifier | |||||||

| D309 | |||||||||

| D373 | Traction motor for electric locomotive | ||||||||

| D374 | Porous, high resistivity, good commutation performance | High-speed DC motors with difficult commutation, traction motors, exciters of turbo-generators, rolling motors | |||||||

| D479 | Difficulty commutating DC motors | ||||||||

| J101 | High copper content, low resistivity, high allowable current density | Low-voltage, high-current DC generators, such as: DC generators for electrolysis, electroplating, and charging, and collector rings for wound-rotor asynchronous motors | |||||||

| J102 | |||||||||

| J164 | |||||||||

| J104 | Low-voltage, high-current DC generators, generators for cars and tractors | ||||||||

| J104A | |||||||||

| J201 | Medium copper content, high resistivity, high copper content, large brush, and high allowable current density | Low-voltage, high-current DC motors with voltages below 60V, such as: automotive generators, DC welding machines, collector rings of wound rotor asynchronous motors | |||||||

| J204 | Low-voltage, high-current DC motors with voltages below 40V, automotive auxiliary motors, and collector rings of wound rotor asynchronous motors | ||||||||

| J205 | DC generators with voltages below 60V, DC starter motors for automobiles and tractors, slip rings for wound rotor asynchronous motors | ||||||||

| J206 | Small DC motors with 25-80V voltage | ||||||||

| J203 | Low copper content, higher resistivity than high and medium copper content brushes, lower allowable current density | High-current charging generators with voltages below 80V, small traction motors, collector rings for wound rotor asynchronous motors | |||||||

| J220 | |||||||||

| Brush bristles performance and working conditions | |||||||||

| model | Resistivity (μΩ.m) | A pair of brush contact voltage drop (V) | 50H wear≤(mm) | Recommended working conditions | |||||

| basic value | Volatility ±% | basic value | Volatility ±% | Rated current density (A/cm | Permissible peripheral speed (m/s) | Brush unit pressure (Pa) | |||

| S3 | 13 | 30 | 2.1 | 25 | 0.2 | 11 | 25 | 19600~24500 | |

| S6 | 20 | 30 | 1.8 | 25 | 0.2 | 12 | 70 | 14700~19600 | |

| D104 | 10 | 40 | 2.4 | 20 | 0.25 | 12 | 40 | 14700~19600 | |

| D106 | 9 | 40 | 2.3 | 20 | 0.25 | 12 | 40 | 14700~19600 | |

| D172 | 13 | 40 | 2.7 | 20 | 0.2 | 12 | 70 | 14700~19600 | |

| D172NM | 15 | 40 | 2.1 | 20 | 0.2 | 10 | 70 | 14700~19600 | |

| D202 | 20 | 25 | 2.5 | 25 | 0.15 | 10 | 45 | 19600~24500 | |

| D213 | 29 | 25 | 2.6 | 25 | 0.15 | 10 | 40 | 19600~39200 | |

| D214 | 28 | 25 | 2.4 | 25 | 0.15 | 10 | 45 | 19600~39200 | |

| D215 | 30 | 25 | 2.8 | 25 | 0.15 | 12 | 40 | 19600~24500 | |

| D252 | 15 | 30 | 2.5 | 25 | 0.15 | 12 | 12 | 14700~24500 | |

| D280 | 15 | 25 | 2.5 | 25 | 0.2 | 10 | 60 | 19600~39200 | |

| D308 | 40 | 30 | 2.6 | 35 | 0.15 | 10 | 40 | 19600~39200 | |

| D308L | 43 | 30 | 3 | 35 | 0.15 | 10 | 40 | 19600~39200 | |

| D309 | 39 | 30 | 2.9 | 35 | 0.15 | 10 | 40 | 19600~39200 | |

| D312 | 35 | 30 | 2.5 | 35 | 0.1 | 12 | 50 | 19600~39200 | |

| D374D | 44 | 30 | 2.7 | 35 | 0.25 | 12 | 50 | 19600~39200 | |

| D374B | 57 | 30 | 2.8 | 35 | 0.25 | 12 | 50 | 19600~39200 | |

| D374D | 45 | 30 | 2.6 | 35 | 0.2 | 12 | 50 | 19600~39200 | |

| D374F | 57 | 30 | 2.7 | 35 | 0.2 | 12 | 50 | 19600~39200 | |

| D374L | 50 | 30 | 2.9 | 35 | 0.12 | 12 | 50 | 19600~39200 | |

| D374BL | 52 | 30 | 2.8 | 35 | 0.15 | 12 | 50 | 19600~39200 | |

| D374DL | 45 | 30 | 3.4 | 35 | 0.15 | 12 | 50 | 19600~39200 | |

| D374N | 58 | 30 | 2.8 | 35 | 0.2 | 12 | 60 | 19600~39200 | |

| D374S | 57 | 30 | 2.8 | 35 | 0.2 | 12 | 50 | 19600~39200 | |

| D376 | 60 | 30 | 2.9 | 35 | 0.25 | 12 | 50 | 19600~39200 | |

| D376N | 62 | 30 | 2.9 | 35 | 0.2 | 12 | 60 | 19600~39200 | |

| D376Y | 62 | 30 | 2.9 | 35 | 0.2 | 12 | 50 | 19600~39200 | |

| D464F | 40 | 40 | 2.5 | 25 | 0.15 | 10 | 40 | 19600~39200 | |

| D479 | twenty four | 40 | 2 | 25 | 0.25 | 12 | 40 | 19600~39200 | |

| J100 | 0.06 | 50 | ≤0.5 | / | 0.8 | 20 | 20 | 17640~22540 | |

| J101 | 0.12 | 50 | 0.25 | 40 | 0.8 | 20 | 20 | 17640~22540 | |

| J102 | 0.23 | 50 | 0.5 | 40 | 0.4 | 20 | 20 | 17640~22540 | |

| J103 | 0.23 | 50 | 0.5 | 40 | 0.4 | 20 | 20 | 17640~22540 | |

| J104 | 0.05 | 50 | 0.25 | 40 | 0.8 | 20 | 20 | 17640~22540 | |

| J105 | 0.06 | 50 | ≤0.4 | / | 0.8 | 20 | 20 | 17640~22540 | |

| J133 | 0.13 | 50 | ≤0.5 | / | 0.6 | 20 | 20 | 17640~22540 | |

| J151 | 0.09 | 50 | 0.3 | 40 | 0.6 | 25 | 20 | 17640~22540 | |

| J164 | 0.09 | 50 | 0.3 | 40 | 0.7 | 20 | 20 | 17640~22540 | |

| J201 | 3.5 | 60 | 1.5 | 45 | 0.18 | 15 | 25 | 14700~19600 | |

| J203 | 8.8 | 50 | 1.8 | 35 | 0.15 | 12 | 20 | 14700~19600 | |

| J204 | 0.6 | 60 | 1.1 | 45 | 0.3 | 15 | 20 | 19600~24500 | |

| J205 | 6 | 60 | ≤2 | / | 0.5 | 15 | 35 | 14700~19600 | |

| J206 | 4 | 50 | 1.5 | 35 | 0.3 | 15 | 25 | 14700~19600 | |

| J213 | 0.55 | 60 | 0.7 | 45 | 0.4 | 15 | 20 | 19600~24500 | |

| J220 | 6 | 50 | 1.4 | 35 | 0.2 | 12 | 20 | 14700~19600 | |

| R051 | 35 | 30 | 3.7 | 30 | 0.15 | 8 | 40 | 14700~19600 | |

-

- Máy sấy gió nóng hình vuông, square electric heater Rui Fu Te DRF-3KW, DRF-06KW, DRF-09KW, DRF-15KW Liên hệ

-

- Máy sấy gió nóng công suất, electric hot air blower Baogong (BGE) BG-C15/3, BG-C30/3, 15/30KW Liên hệ

-

- Lò xo nén chổi than, YZR carbon brush stainless steel constant pressure spring YZR112/132/160/180/200/250/280 Liên hệ

-

- ĐỘNG CƠ ĐIỆN 3 PHA Y SERIES Liên hệ

-

- CHỔI THAN MORGAN D172 25X32X60MM Liên hệ

TÂN THÀNH CAM KẾT

- Sản phẩm, hàng hóa chính hãng.

- Giá cả cạnh tranh.

- Dịch vụ chăm sóc khách hàng tận tâm.

Thông Tin Công Ty

Chính sách và quy định

Hỗ trợ khách hàng

THÔNG TIN LIÊN HỆ:

-------------------------------

CÔNG TY TNHH THIẾT BỊ CÔNG NGHIỆP TTH

Trụ sở: số 124 ngõ 79 Yên Hoà-Cầu giấy-HN

Kinh doanh 1 : 0816.861.515

Kinh doanh 2 : 0836.861.515

Kinh doanh 3 : 0926.511.515

Kinh doanh 4 : 0916.861.515

Kinh doanh 5 : 0888.868.515

Kinh doanh 6 : 0917.971.515

Website: http://tanthanh-automation.com

Website: http://thietbitudongtanthanh.com

Website: http://diencongnghieptanthanh.com

Email: tthkinhdoanh@gmail.com

Email: tthkinhdoanh01@gmail.com